DirectCommand L2 Features

Section Control

Control up to 36 boom sections with variable rate application.

Many Supported Applications

From liquid controller to planter, to sprayer or NH3 applicator, controls all of your application machines.

Buildable System to RightSpot

When you are ready to upgrade your system to nozzle-by-nozzle control, you can easily upgrade the DirectCommand L2 system to RightSpot.

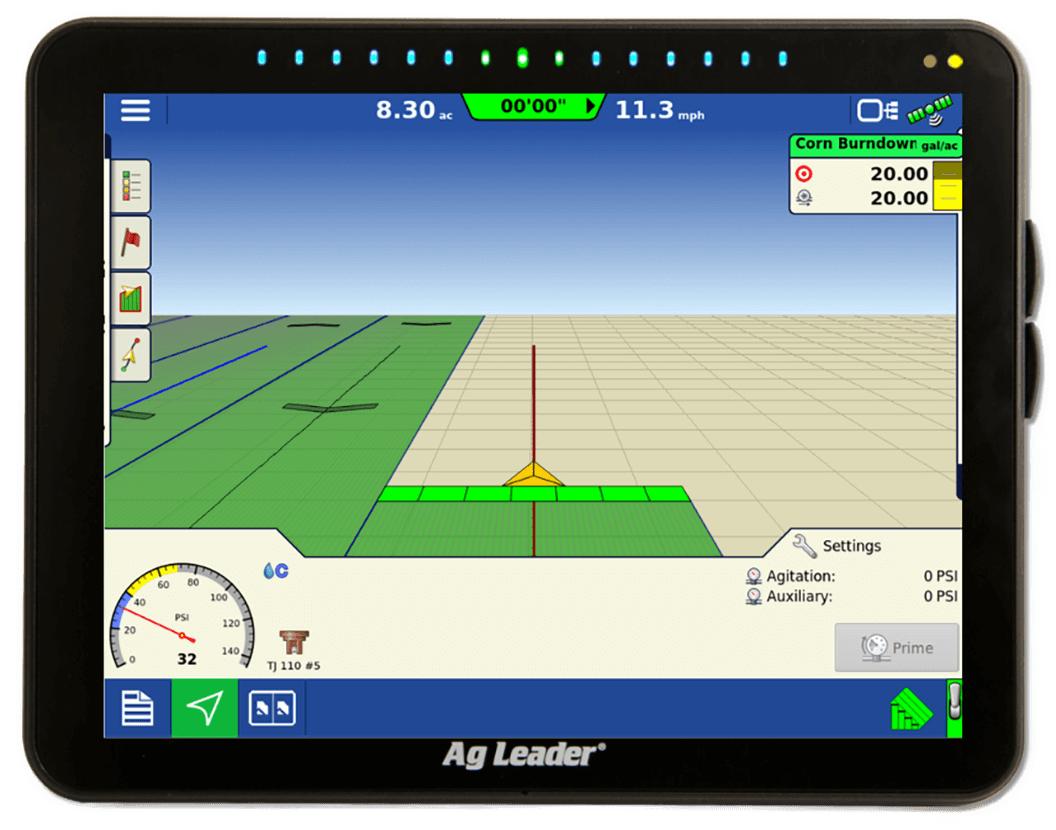

Industry Leading Visibility

Visibility in and out of the cab and year-round control with InCommand including droplet size monitoring.

DirectCommand L2 Features

Section Control

Control up to 36 boom sections with variable rate application.

Many Supported Applications

From liquid controller to planter, to sprayer or NH3 applicator, controls all of your application machines.

Buildable System to RightSpot

When you are ready to upgrade your system to nozzle-by-nozzle control, you can easily upgrade the DirectCommand L2 system to RightSpot.

Industry Leading Visibility

Visibility in and out of the cab and year-round control with InCommand including droplet size monitoring.

When it Comes to Application, Be InCommand

AutoSwath

Reduces overapplication and product waste by automatically turning the applicator on/off based on field boundaries and already-applied areas as it passes over the field. Control up to 36 boom sections.

Visibility in cab and out

InCommand gives you instant visibility in the cab to your sprayer’s performance. Access your maps and field information anytime, anywhere when everything is automatically synced to all your devices through AgFiniti.

Boom Pressure Map

Enhance your record keeping and visibility with boom pressure and droplet size data that is logged and mapped automatically.

Easy Reporting

Automatically generate SmartReports that provide location, product information, applied totals, as-applied maps and more right from the display.

Diagnostics

Monitor the status of every nozzle valve across the boom with a single display. If there’s a problem that could affect system performance, InCommand will alert the operator to take action.

When it Comes to Application, Be InCommand

Supported Machines

Spinner Spreader Control

Apply up to five products with control based on spinner speed and bin-level monitoring. Container sequencing allows for sequential application of multiple products.

Conventional Sprayer

Starting with DirectCommand L2 for section control, you have a buildable system if you want to upgrade to Ag Leader’s individual nozzle control system, RightSpot for added precision. Learn more here.

NH3/Anhydrous Toolbars

Vapor State Monitoring: See onscreen when the product is in a liquid or vapor state and susceptible to product volatility or could damage the flow meter.

Tube Check: Easily see if there are any applicatin tubes plugged when the cab implement is raised, allow you to remain safely in the cab.

Planter

Ag Leader offers a range of rate control options to fit the grower’s unique liquid setup on a planter. DirectCommand can control electric pumps by adding the DC Motor Driver or a complete wiring install will connect to the planter’s liquid control valve, flowmeter, and optional section control valves.

Contact a Dealer to Learn More

Get more done together with DisplayCast

When Your Machines Can Talk, It’s Amazing How Productive You Can Be

Connect all your InCommand Displays whether working in the same field, different fields, or from one season to the next. Efficiency in your operation increases when you’re connected.