SureForce™ VS. Springs in No-Till and Conventional Till

SureForce is a hydraulic downforce and uplift system that automatically adjusts the right amount of force on each row to achieve optimum and uniform seed depth in the field. While the optimum depth for corn is generally universal no matter where you are located, your ground and farming practices can make a big difference in what you need to do to achieve that depth – especially tillage practices.

So we set out to answer – How does SureForce perform compared to springs in a no-till environment and a conventional tillage environment. While there are many factors at play- we found some trends in a recent trial conducted in Ohio.

Tech Trial Highlights

Location: Ohio

Planter: 16- row Kinze 3600

Tech: Rows one through eight were equipped with the factory downforce springs. Rows nine through sixteen were equipped with SureForce.

Tillage: The grower performed trials in both no-till and conventional tilled fields.

Planting Date Range

Trial 1: No-till field

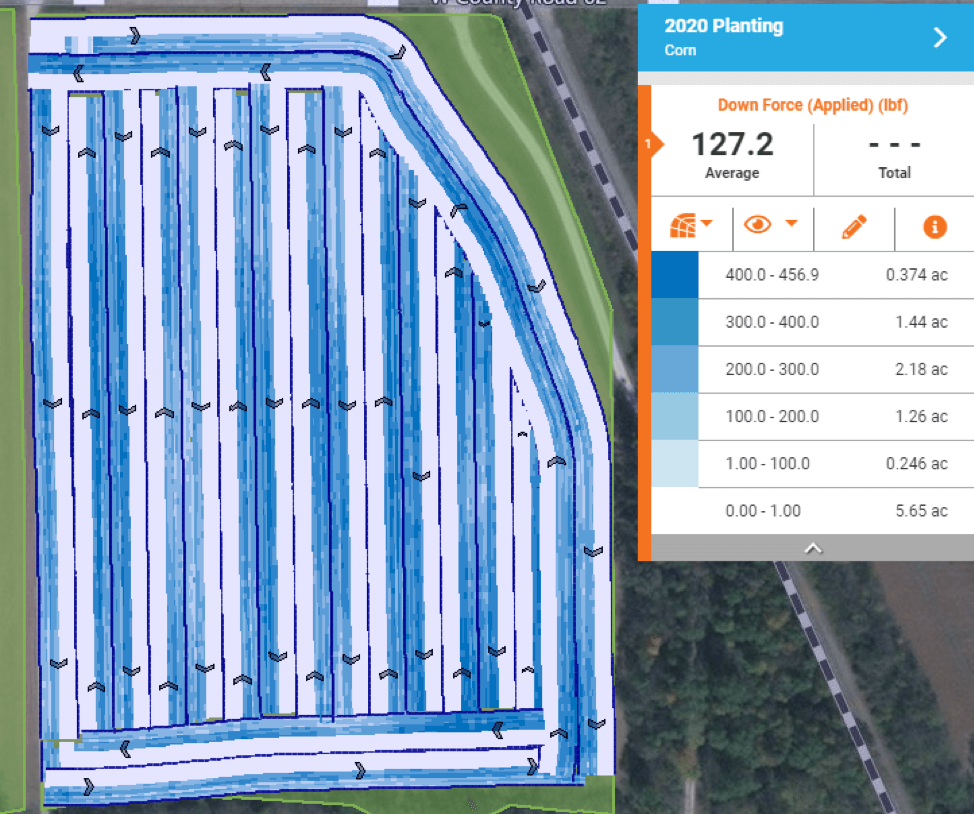

The soil conditions in this no-till field were hard and compact, requiring higher amounts of force to place seed at the proper depth. For this field the factory springs were set at their highest downforce setting, which provide about 300 lbs. of force to the row unit. In Figure 1, shown below, SureForce (blue) operated mostly around the 200-300 lb. range. This means that the white areas of the map that had conventional downforce springs set to their heaviest was right where they should be.

However, SureForce still operated a significant portion of the time in the 100-200 lb. range, and even dipped into the 300-400 lb. range. While SureForce is able to react to changing ground conditions throughout this 11–acre field, the factory springs are often applying too much downforce, causing compaction. At other times the factory springs are applying too little downforce, causing shallow planted seeds.

Preventing Uneven Emergence

Spring of 2020 provided exceptionally dry weather, which allowed planters to hit the fields in a timely fashion. While dry planting conditions are generally preferred over wet conditions, there are some pitfalls to be aware of. The most widespread issue this spring was planting too shallow.

Incorrectly planting seeds too close to the soil surface exposes them to varying moisture levels compared to seeds planted deeper in the soil. This creates more issues when some seeds access more or less moisture than the others, eventually leading to uneven emergence.

In Figure 2, the seeds were planted with the factory springs, applying about 300 lbs. of downforce, whereas the SureForce system was applying 350 lbs. on the adjacent rows. Uneven emergence was found on the half the planter equipped with springs.

Here, uneven emergence is caused by a difference in moisture levels indicated around the seed. With less than a ½” depth variation, this is a painful example of how just a slight difference in seed placement can reduce yields and profits.

Figure 2

Figure 2

Next, let’s take a look at other areas of the field that didn’t require as much force to achieve depth. In those areas, the factory spring system was still applying 300 lbs. downforce, while the SureForce system had automatically reduced the downforce to 100 lbs.

What happens in these areas where the springs are applying 200 lbs. too much of downforce? This next picture (Fig.3) illustrates what happens.

Figure 3

Roots that can’t penetrate the wall of a compacted seed trench are forced to grow along the trench, which is the path of least resistance. When roots can’t grow downward, they can’t access moisture and nutrients resulting in reduced yield and profit.

Trial 2: Conventionally Tilled Field

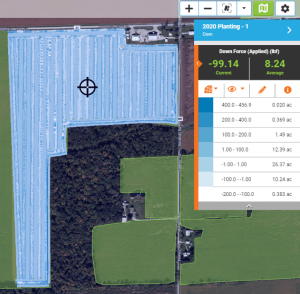

Next, this planter moves to a conventionally tilled field (Fig. 4) to continue planting. The factory springs are left at a heavy setting. Since the SureForce system automatically adjusts itself to current ground conditions, we see a stark difference in applied downforce. Within this field, SureForce values range from 200 lbs. of uplift on the row-unit to 400 lbs. of downforce. That is a 600 lb. range across this field.

Figure 4

We went to an area of the field where SureForce was providing uplift, thus reducing compaction. On the other hand, in the adjacent rows the factory spring settings are fixed and are not capable of adjusting automatically, which caused some compaction damage.

SureForce Proves Advantageous to Plant Development

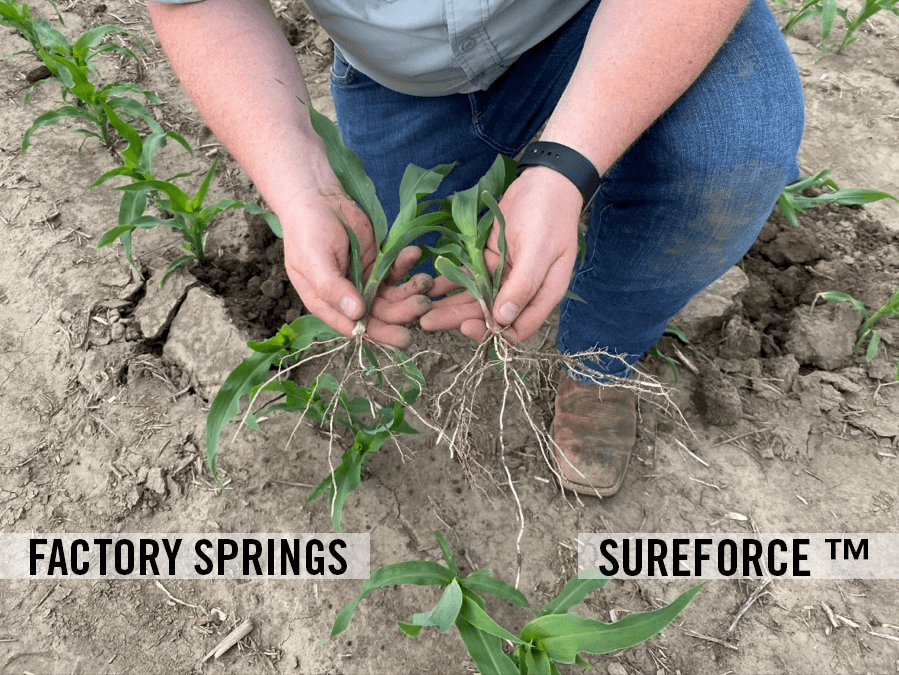

Visual plant health differences were observed at V3-V4 growth stages on June 10, 2020. Below in Figure 5, the rows to the right were equipped with SureForce. The rows to the left were equipped with factory downforce springs.

Figure 5

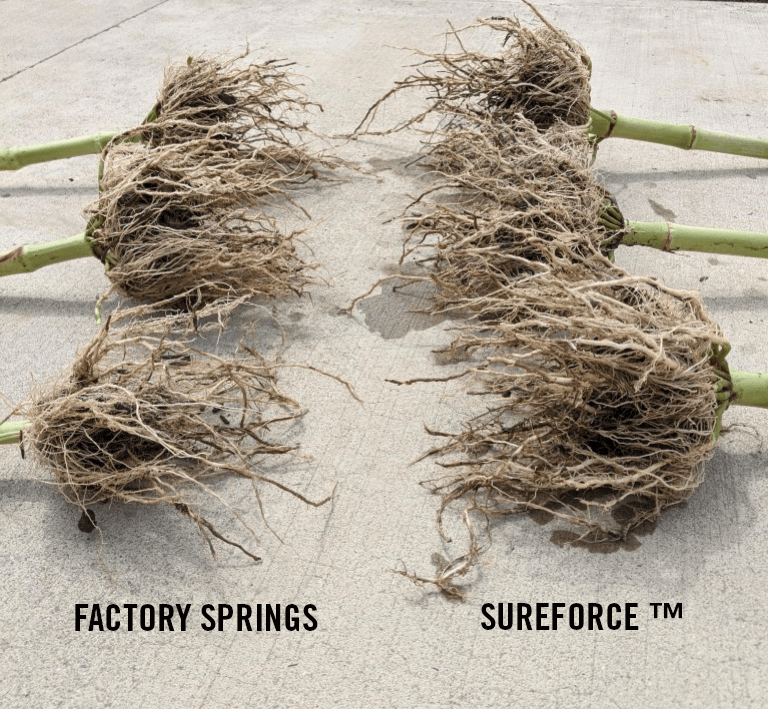

To better understand the “root” cause of these health differences seen above ground, we took a look below ground.

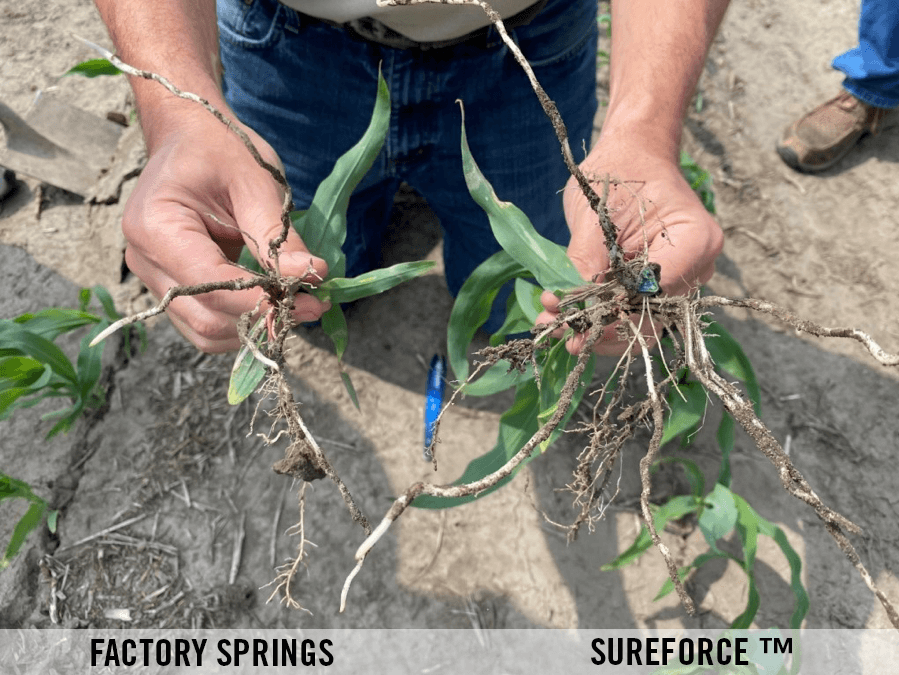

Figure 6

Figure 7

In Figures 6 and 7 above, it is obvious the rows equipped with SureForce provided the best root development. In every case, SureForce provided:

- Deepest radical and seminal roots

- Widest branching of nodal roots

- Great root hair development

On June 10th, it was clear the rows planted with SureForce were off to a much better start. From seed to soil contact these rows were positioned to provide increased yield and profit.

A return trip on August 11th, 2020 continues to show not only greater root development as seen in Figure 8, but also larger ears are observed with less tip-back as seen in Figure 9.

Figure 8

Figure 9

Stay tuned for yield comparison coming this winter!

Check out stories from past trials for no-till and conventional till fields.

Give your local Ag Leader dealer a ring and find out about what’s working best in your area and what might be right for your farm.