BoomLoop Features

Fully Integrated Recirculation Solution

Paired with RightSpot, BoomLoop creates a streamlined path for product to flow from the ends of the boom and back to the tank, eliminating dead spots and opportunities for buildup.

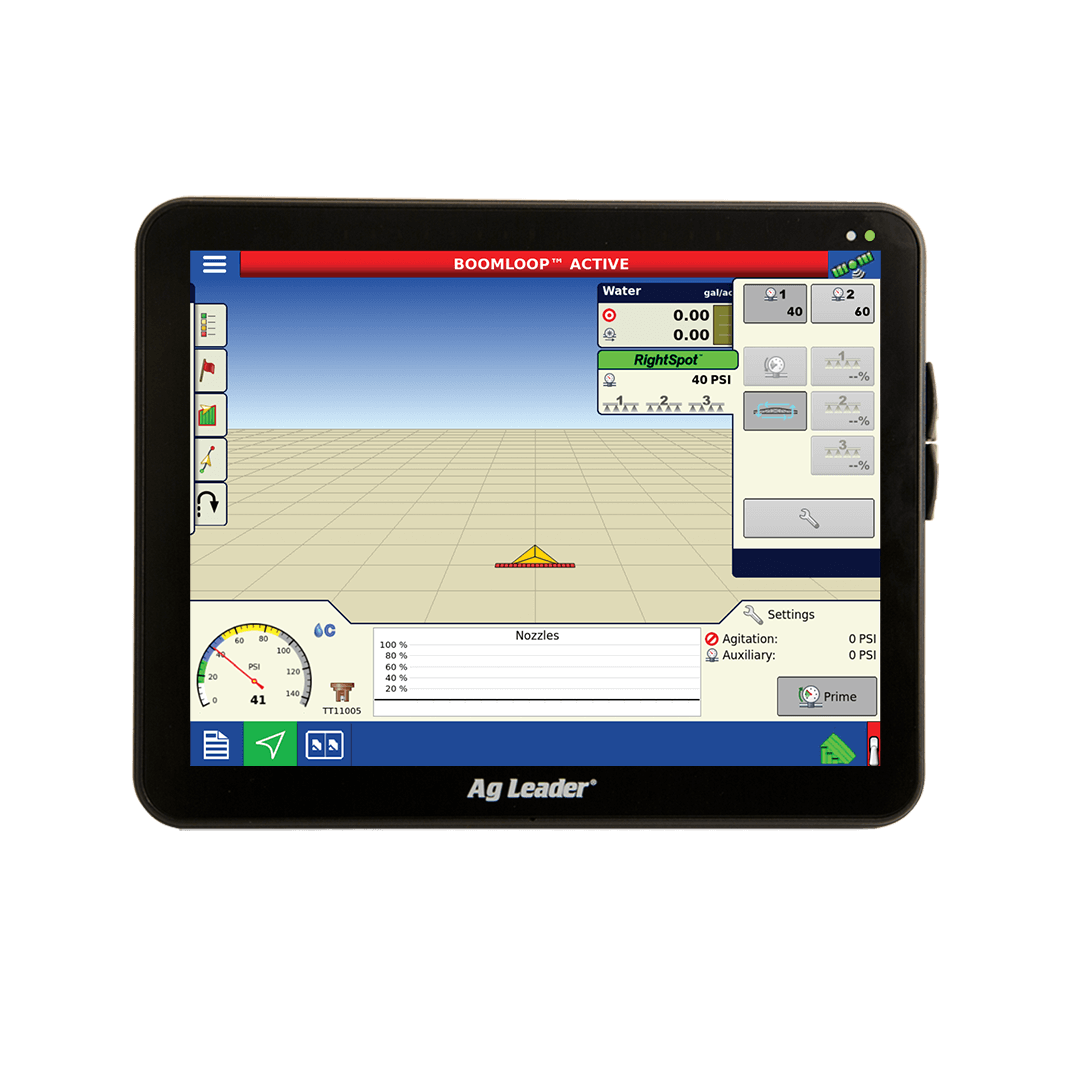

Visibility Through The InCommand® Display

View and control BoomLoop through the InCommand display – the same interface used in the cab to steer, apply, and more.

Automated Priming

BoomLoop automates the priming process to ensure the spray solution from the tank fills the entire boom without dispensing product to the ground.

Convenient Sequencing

The automatic sequencing of the section valves ensures the entire boom is fully primed or flushed even when the boom is folded or not sitting level.

Avoid Application Mishaps

Spraying with an unprimed boom has serious consequences. The operator may forget to prime the boom or primed it inadequately, leading to water retention. Once the issue is noticed, it’s often too late – either the weeds have become too tall for control or the effective chemistry window has passed. Fixing this error requires effort, such as mixing a 5-acre batch of chemical and going through the process of cleaning out the sprayer again. Unfortunately, these mistakes often go unresolved, impacting the entire growing season.

Recirculate On-The-Go

Get a Quote

Get more done together with DisplayCast

When your machines can talk, it’s amazing how productive you can be!

Connect all your InCommand displays whether working in the same field, different fields, or from one season to the next. Efficiency in your operation increases when you’re connected.