RightSpot Features

Nozzle-by-Nozzle Control

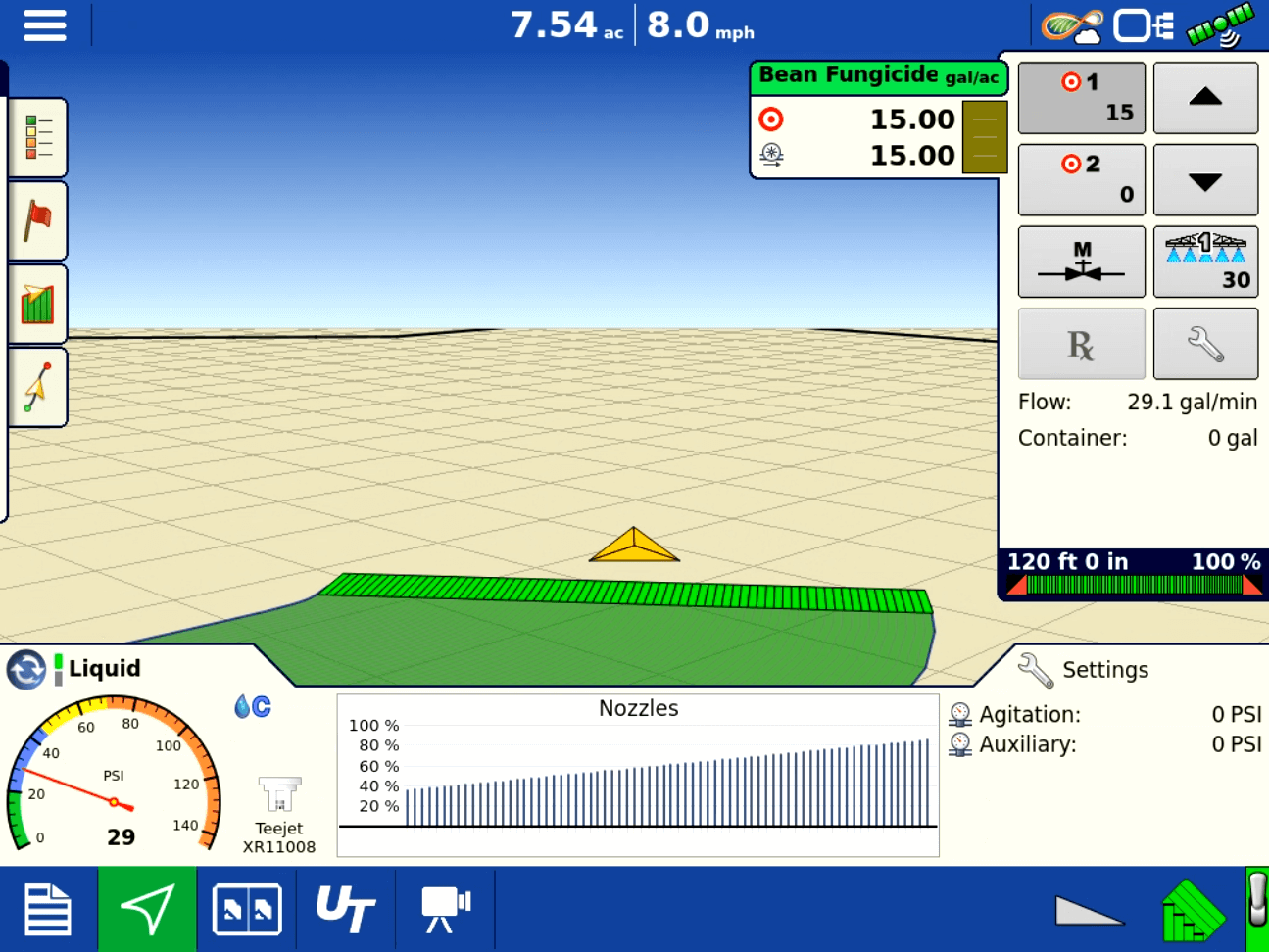

Instant nozzle by nozzle swath control. Up to 144 nozzles supported.

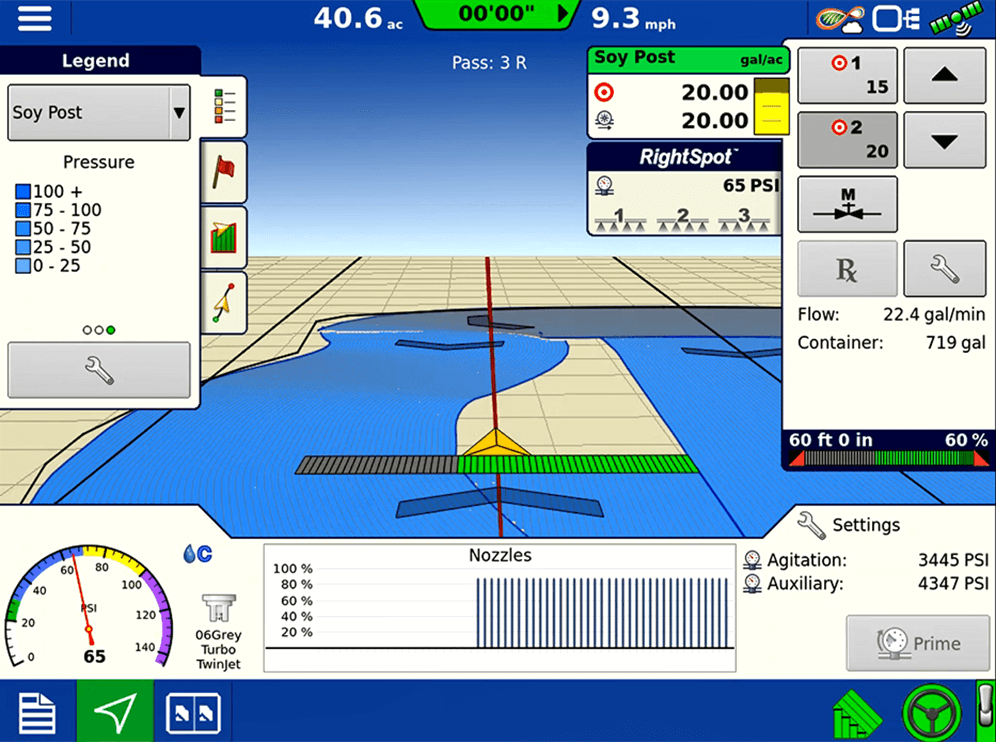

Consistent Coverage Across Any Terrain

Flow rate and pressure are controlled independently, allowing for a consistent rate across a variety of conditions.

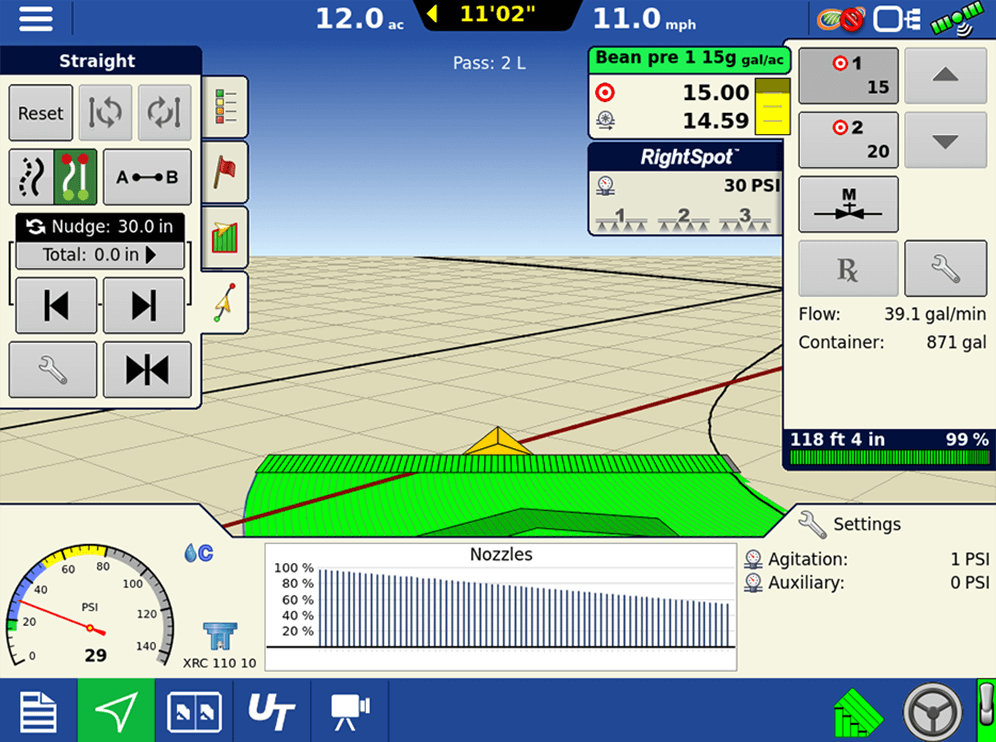

Increased Productivity and Speed

Speed up or slow down, accurate at a wider range of speed.

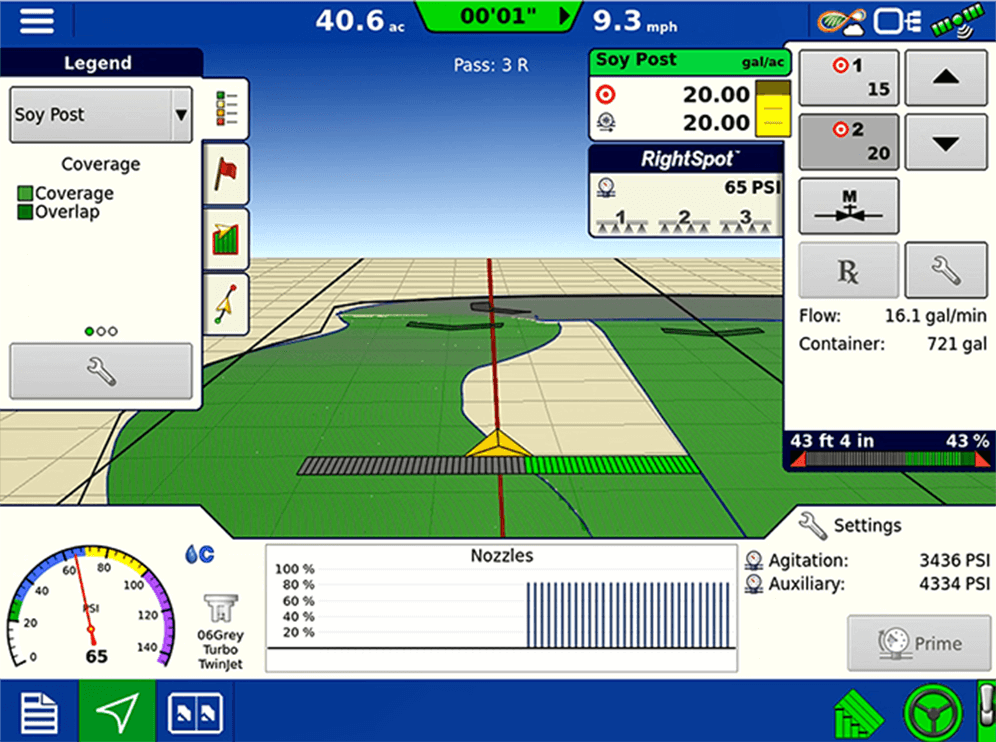

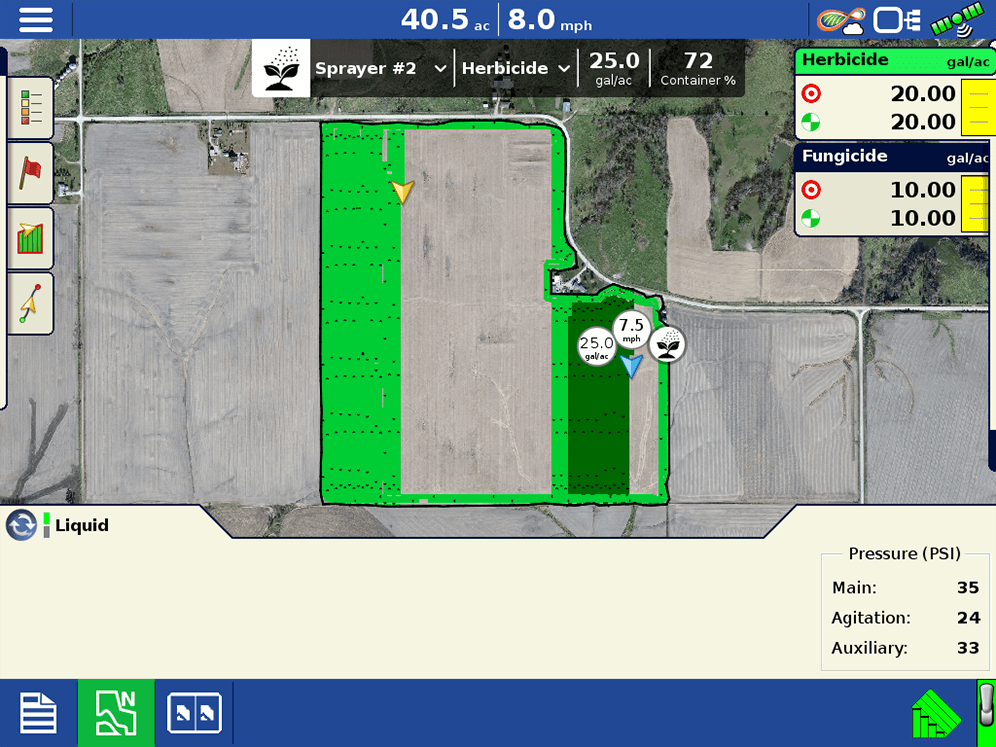

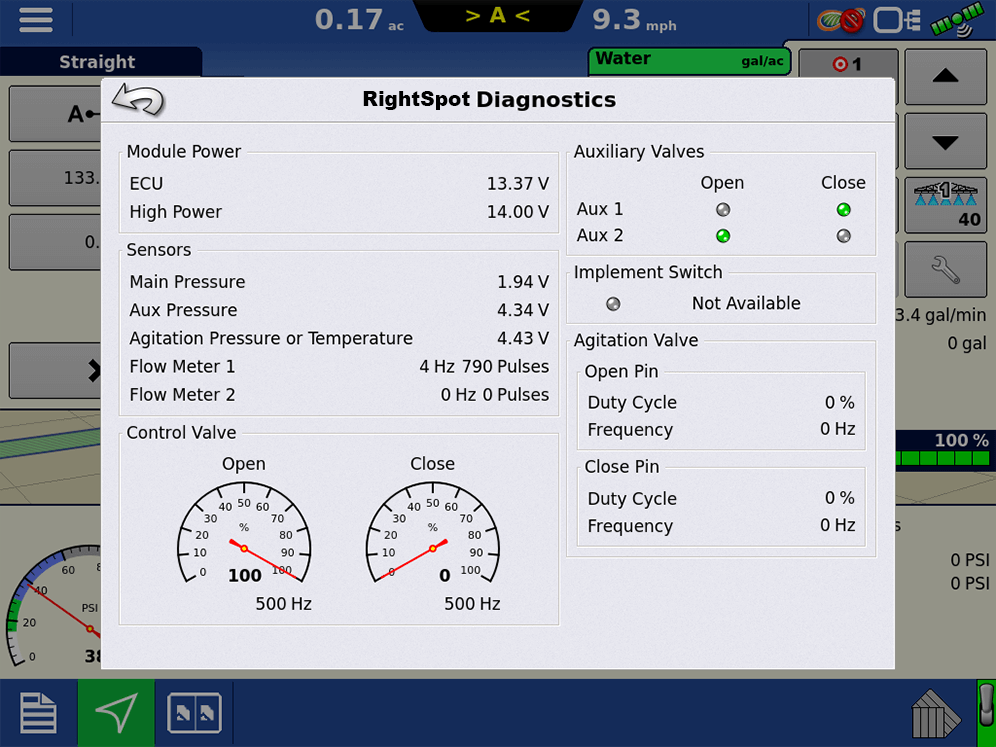

Industry Leading Visibility

Visibility in and out of the cab and year-round control with InCommand.

RightSpot Features

Nozzle-by-Nozzle Control

Instant nozzle by nozzle swath control. Up to 144 nozzles supported.

Consistent Coverage Across Any Terrain

Flow rate and pressure are controlled independently, allowing for a consistent rate across a variety of conditions.

Increased Productivity and Speed

Speed up or slow down, accurate at a wider range of speed.

Industry Leading Visibility

Visibility in and out of the cab and year-round control with InCommand.

Design

Increased Visibility Throughout The Operation

Controlled through the year-round InCommand 1200 display which connects to other displays and devices across the farm.

Scalable Architecture

Propriety liquid control system enabling scalability from section control up to advanced nozzle-by-nozzle level control.

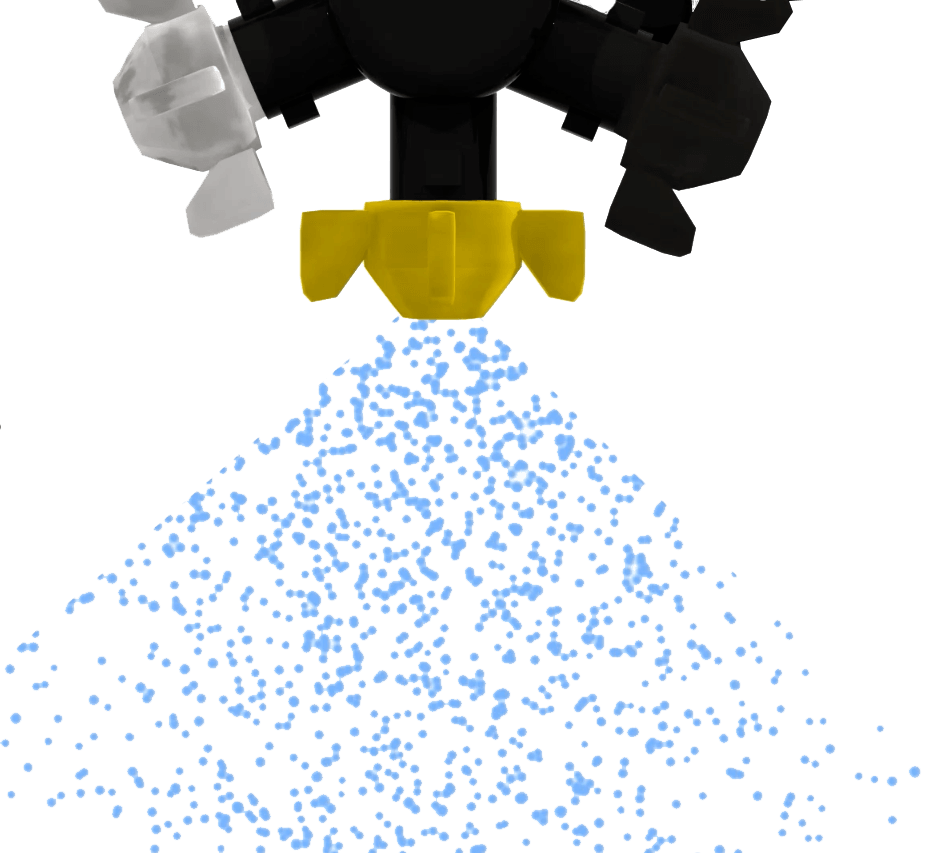

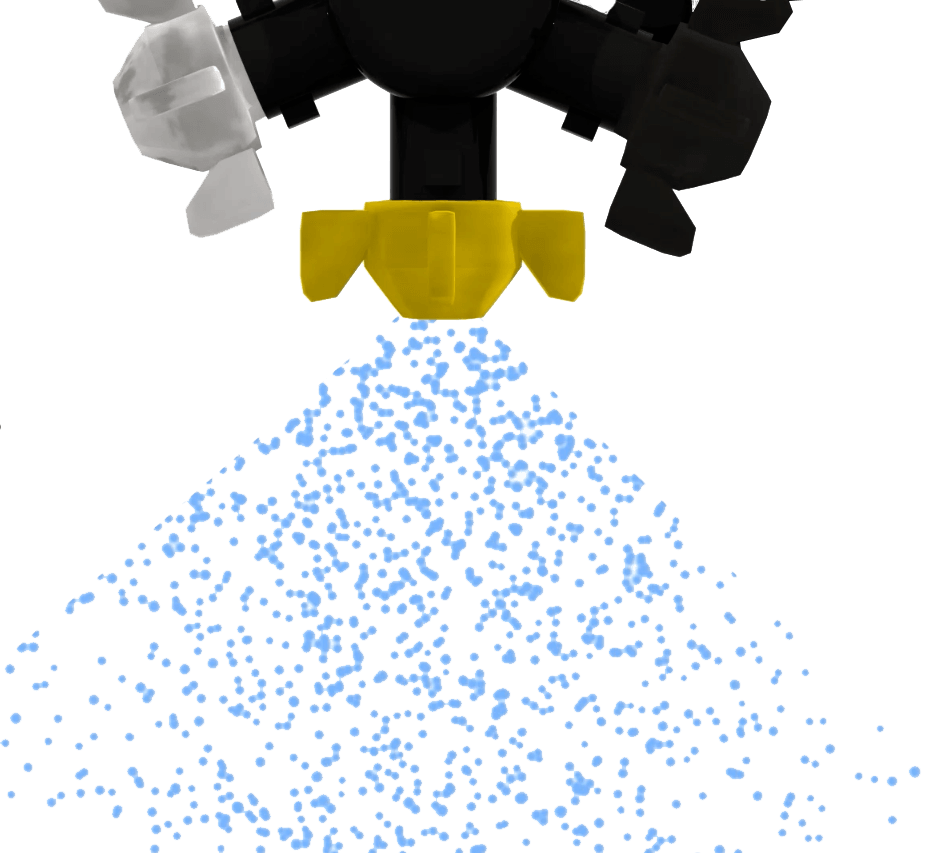

Blended Pulse Technology®

Blended Pulse technology controls flow rate through electric solenoids that alternate pulsing at 10 or 20 Hz frequency which eliminates skips in the spray pattern.

Fits On Many Makes And Models

Fits on most common brands and models of self-propelled sprayers and pull-type sprayers including John Deere, Case, Hagie, Rogater, Apache and more to come.

Clean Install

Cabling designed specific for varying boom widths & nozzle spacing result in a clean and simple install.

Tech Specs

PWM System

Designed for a single boom line and one nozzle valve at each location.

Up To 144 Nozzles Supported

Up to 144 nozzles with standard 15 series valves. 110 nozzles supported with high-rate 24 series valves.

Nozzle Bodies Supported

Hypro/Arag, TeeJet and Wilger

For Standard Spraying Functions

Utilize the 15 Series Valve to achieve 1.5 gal/minute max flow per nozzle valve with the appropriate nozzle size.

For Higher Flow Application Needs

Utilize the 24 Series Valve to achieve 2.4 gal/minute max flow per nozzle valve with the appropriate nozzle size.

Now Available: BoomLoop™

Introducing BoomLoop™, an upgrade for sprayers equipped with the RightSpot™ nozzle-by-nozzle control system. An automated recirculation solution, BoomLoop is seamlessly integrated into the InCommand display and provides sprayer operators a simple, effective way to prime, reagitate, and flush boom contents.

When it Comes to Application, Be InCommand

When it Comes to Application, Be InCommand

A nozzle-by-nozzle advantage

RightSpot uses Blended Pulse® technology to achieve consistent coverage and reduced skips. Pulsing nozzles maintain a precise user-defined boom pressure allowing the operator to achieve a consistent rate and droplet size at a wider variety of speeds and across difficult terrain.

Inconsistent droplet size = coverage issues

Without nozzle-by-nozzle technology, achieving consistent coverage across the entire field is difficult. RightSpot monitors and maintains the right droplet size prescribed for the product, ensuring the right amount of product applied to do its job effectively while reducing risk of drift to neighboring crops.

Inconsistent droplet size = coverage issues

Without nozzle-by-nozzle technology, achieving consistent coverage across the entire field is difficult. RightSpot monitors and maintains the right droplet size prescribed for the product, ensuring the right amount of product applied to do its job effectively while reducing risk of drift to neighboring crops.

Get a Quote

How coverage is affected by speed

No field is the same. Regardless of the field, applying at just one speed doesn’t feel quite right. There may be some challenging areas where you feel more comfortable slowing down. In open areas you may want to cover more ground faster.

Traditional

A traditional sprayer demands spraying at a consistent speed regardless of field conditions because it regulates application rate by increasing or decreasing boom pressure as speed changes. When you are traveling slower than your optimum speed range, your pressure is too low and your spray droplet size is too big to get effective coverage. And vice versa for traveling too fast.

RightSpot

RightSpot makes operating the sprayer less stressful. Flow rate and pressure are controlled independently, enabling you to spray at a comfortable speed for your field conditions while maintaining desired rate and droplet size consistently. It gives you the power to get the job done more efficiently and effectively – speed up in open areas or slow down when difficult terrain calls for it.

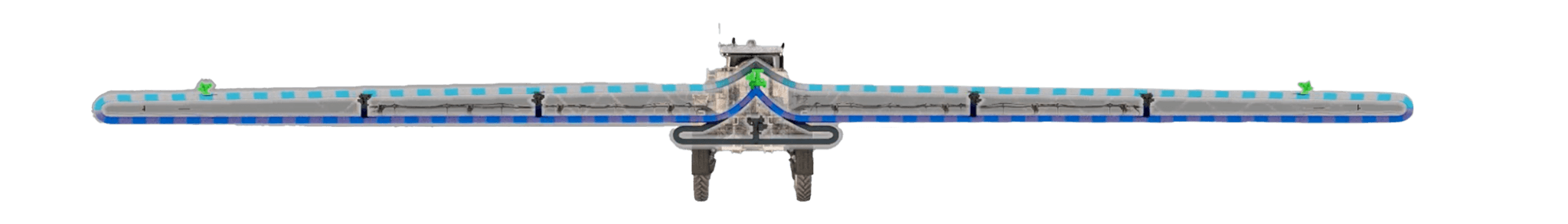

How coverage is affected around curves

Weeds keep popping up around the edges of your field? There’s no hiding just how precise your sprayer is when applying around curves, terraces, and field edges.

With turn compensation and individual nozzle control, your field edges look just as good as the rest of your field. Apply just the right amount with a consistent rate applied on the inner and outer portions of the boom.

When spraying around a contour, the rate can be significantly higher on the slower-moving inside part of the boom, and significantly lower on the faster-moving outside part of the boom. Applying incorrect rates contributes to costly issues such as potential crop damage, pest resistance and product waste.

When spraying a curved path, RightSpot increases the flow on the faster-moving outer nozzles while decreasing the flow on the slower-moving inner nozzles. This prevents over- or under-application on any part of the field, achieving accurate rate in all areas.

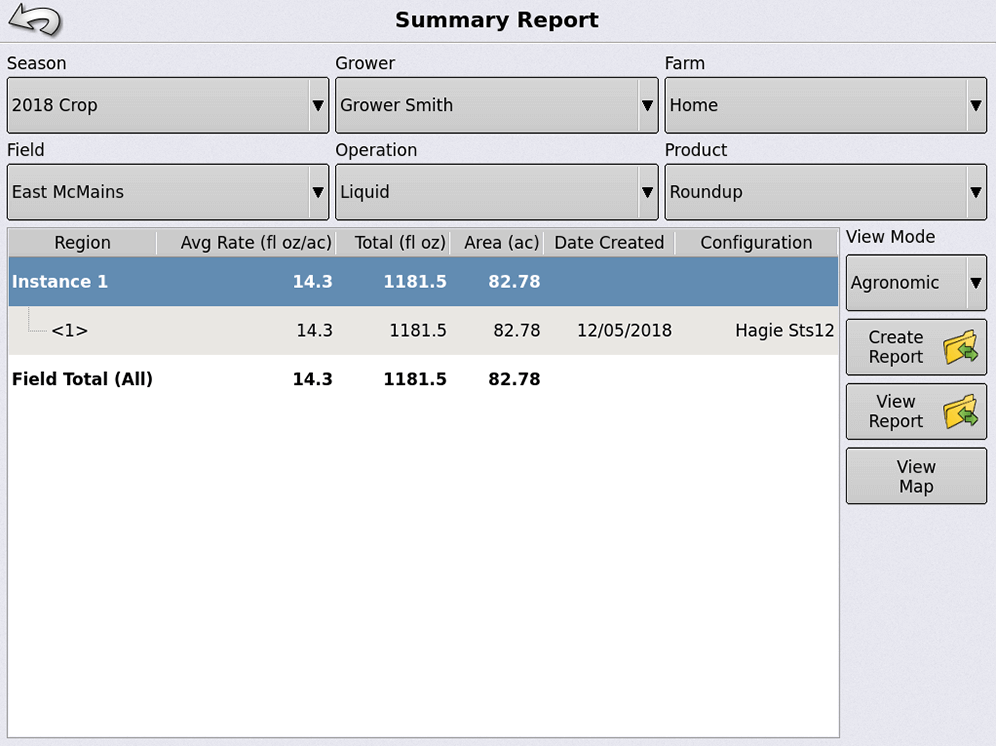

Get more done together with DisplayCast

When Your Machines Can Talk, It’s Amazing How Productive You Can Be

Connect all your InCommand Displays whether working in the same field, different fields, or from one season to the next. Efficiency in your operation increases when you’re connected.